So today was a good day for radio. I had a block of time and wanted to see how hard it would be to get the activation only on FT8. I know it is possible to do this, but I also wanted to do it on 15 meters too and that is where the problems come in. You see the last couple of weeks have been tough for 15 meters operations what with the solar flares and CMEs and all. So to secure the activation on the higher bands will be… interesting…

I get to the park and in the spirit of time savings I chose to go to Sitton’s Gulch which is significantly closer and saved me almost and hour of driving (well, 40 minutes as it is 20 minutes on to the operating position at the top of the mountain and another 20 back to the point at the bottom). I also was happy to see the parking lot was almost empty too. This gave me to opportunity to setup in the corner next to the changing sheds which is a good corner for my antenna radials. This gets them out of the way so that people dont trip over them going to and fro…

I set up in short order for the 15 meter band and get started calling CQ. I call for several minutes and then switch over to answering CQ calls that I see in the waterfall for a few more minutes with zilch to show for it. Literally nothing. I am starting to wonder if there was some sort of flare that I was not aware of or some such as that as I was getting stations into the radio but no one could hear me. I chalked it up to that they must have been running a kilowatt and my paltry little 12 watts into a compromise antenna just wasnt getting it done today.

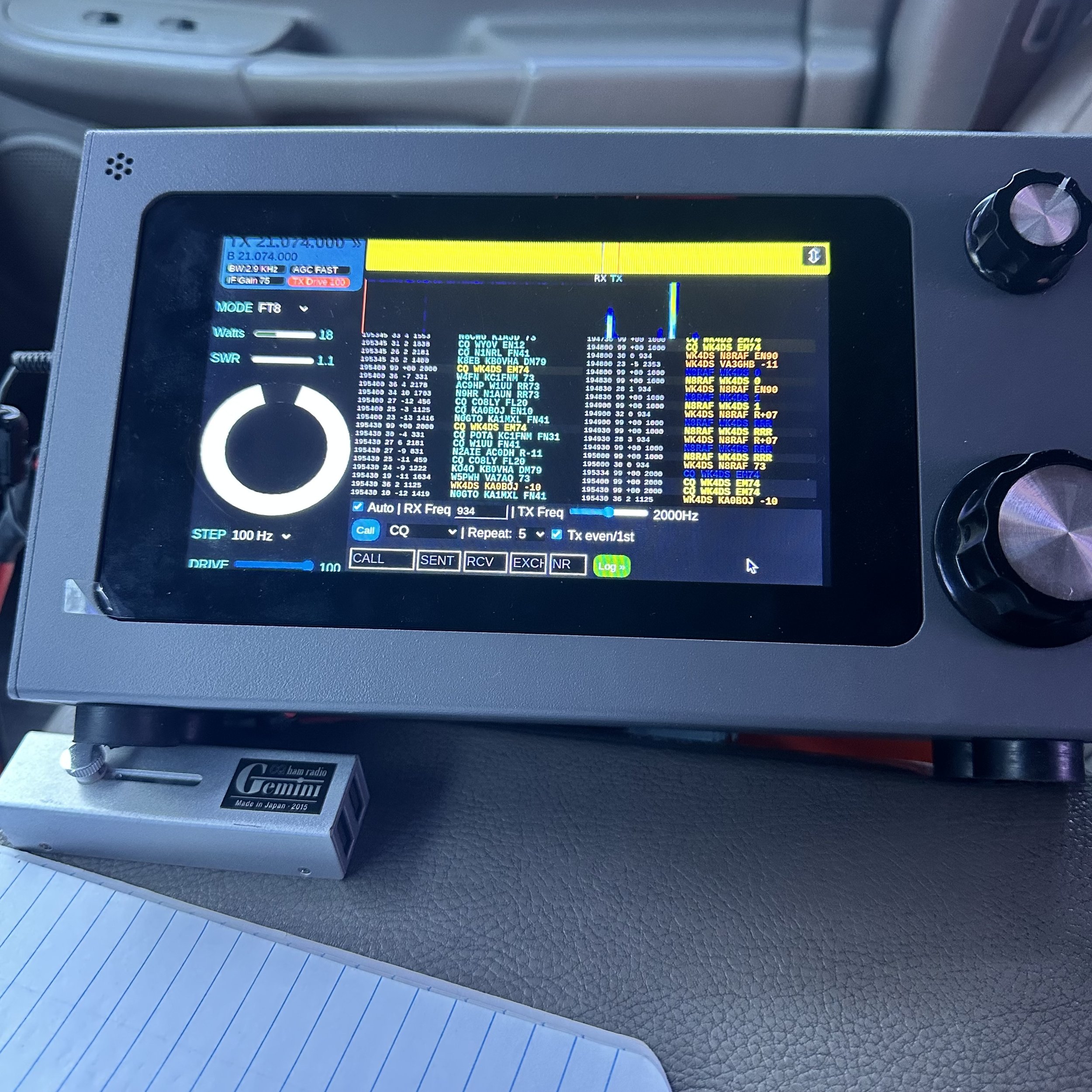

One of the things that I like most about this radio is the clean layout of the FT8 mode. It is not cluttered with an endless array of different information and on screen settings. The other programs, while very versatile and powerful, are rife with buttons and information that really is not needed for simple QSO contacts. The sBitx could be a little easier though so it is not perfect either. One thing that has come up a couple of times is that it needs the ability to be able to sort the information display to just stations calling CQ so you can pick one easier. I agree with this as it can be tough to grab a calling station in that 2.5 second window of time. So being able to sort by CQ would be a big help there. One other thing that is mildly frustrating is that there is no way to scroll the display so if there is a lot of stations on the band then you will not be able to see them all. It pushes them off the top of the screen and then they are just gone.

Today though, there was plenty of room to see both even and odd stations so it was not a problem. I was glad to see there was a good amount of activity on the 17 meter band.

The truck cab sure it a convenient operation center for POTA!!! I find it almost perfect to be honest. It is so close that I have used it all winter without modifications but at some point I do think I want to modify it. I have been considering the Kenwood TS480 as a permanent installation in the truck just for POTA, but then I would still need either a computer or the sBitx to operate FT8 in thr fireld. This just circles back to using this radio like you see in the photo below till something better comes along.

Here is the antenna setup for today along with the nanoVNA I used to measure it while I “tuned” the system. Tuning literally involves just moving the radials around till the SWR reads as low as possible. Sometimes it involves adding another radial to the system to get the SWR below 2:1 (which is my personal high limit) and I have even done odd things like run one REALLY long radial way out to give the lower bands a chance at working. This has worked really well too when I want to use 40 meters with a hamstick.

To answer some obvious questions that will show up, yes, there are two nanoVNAs in the box…long story but I have two now. Haha. The case came from GigaParts as they had a bunch of them at the Huntsville hamfest one year for super good prices and I got a couple of them. This one houses the nanoVNA and multimeter and the other holds all my POTA radials. You can see it above on the truck bed cover. I plan to get more of these at some point as they are super useful containers for small equipment like you see here. That is why I wrote on the lid of the yellow one, plus it identifies it as mine as that is my handwriting too.

As you can see though, I had a pretty good run on 17 meters FT8, securing the successful activation just in this mode alone. I never like to stop at just ten so once I had worked everyone I could hear I moved down to 20 meters and worked two more there before calling QRT and packing up. 20 meters is the campground of POTA these day and if you want to simply claim a quick activation then go there, it should not take long to get your ten if you are pressed for time. I know some people do activations on their lunch break and 20 meters is great for that. If you want a bigger challenge though, move up to the higher bands. Seems here lately that when 15 meters is open I will work a ton of dx stations and the lower I go in the bands to closer to home the stations. So if you have not ventured higher in the bands, I recommend you give it a shot sometime, you will most likely be pleasantly surprised

WK4DS